|

Ductility Optimization |

| HOME | F-ANALYSIS | MAT SCI | ENGINEERING | I-PROPERTY | CONTACT |

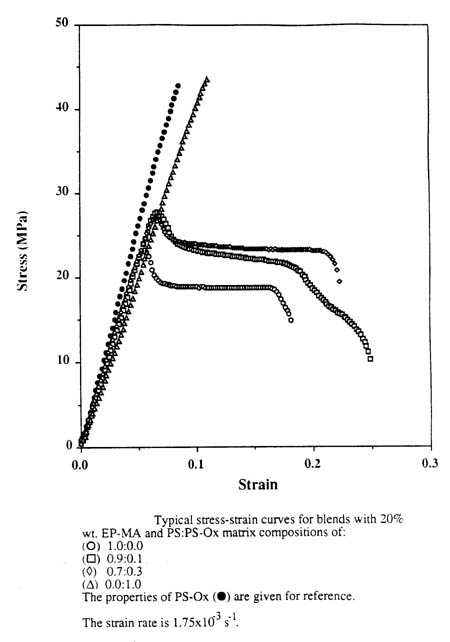

Ductility Optimization in BlendsA blend of polyethylene and ethylene-propylene rubber was being developed for an automotive application. The blended resin exhibited erratic mechanical properties associated with instabilities in the compounding process. These problems were traced to inconsistencies in addition of the reactive compatibilizer for the blend. In practice, the compounder tended to add more compatibilizer "to be sure that the blend was properly compatibilized" if there appeared to be any difficulties during the processing operation. A study was conducted to determine the influence of compatibilizer content on the mechanical properties of the blends. Multicomponent polystyrene/ethylene-propylene rubber blends were prepared by intensive mixing and tested for tensile properties. In each case, the content of polystyrene was 80 wt% and rubber was 20%. However, the amount of compatibilizer in the polystyrene was varied. Mechanical properties were determined by tensile testing. The optimum amount of compatibilizer led to a ductile material and superior mechanical properties. However, the use of too much compatibilizer resulted in a brittle blend. The manufacturing problems were solved by more careful control of the compatibilizer concentration. |

|

|

Copyright 2004-2008 Material Answers LLC |