Defect Reduction in Sheet Extrusion

A manufacturer suffered low process yields due to the

presence of "spots" or "gels" in a plastic sheet product

made from a blend of polyethylene with a ethylene-propylene

copolymer. Gel permeation chromatography of these defects

revealed that they consisted of a poorly dispersed high molecular weight fraction of the copolymer.

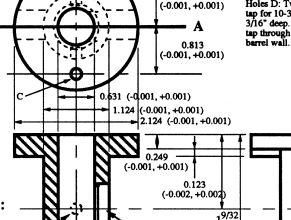

A novel laboratory process simulator was designed and built

to reproduce the material stress and temperature history

as it advanced through the extrusion operation from the

hopper to the sheet die. The primary dispersion mechanism

in the process was identified and a screw profile

modification dramatically reduced the frequency of "gels"

in the final product.

|