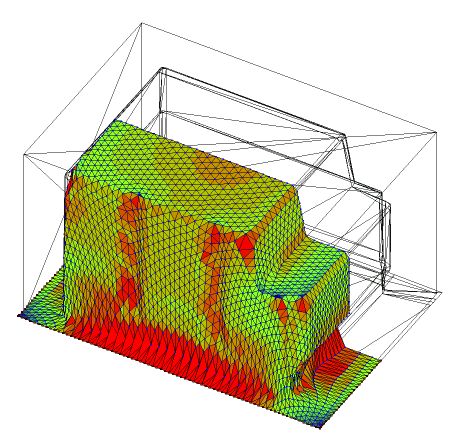

Optimization of Thermoforming

A polymer resin manufacturer needed to improve the processing

robustness of their product in the hands of numerous

customers with widely varying deep-draw thermoforming

operations. We characterized the rheological behavior of

the polymer under flow conditions typically used in thermoforming and utilized this information in a finite

element simulation of a representative production process.

Our analysis revealed the importance of material behavior

in the nonlinear stretching regime after the onset of

nonuniform deformation just prior to ductile failure.

Specific modifications of the polymer composition

were recommended to widen the processing window and

reduce rejects in manufacturing.

|