|

The RSM |

| HOME | F-ANALYSIS | MAT SCI | ENGINEERING | I-PROPERTY | CONTACT |

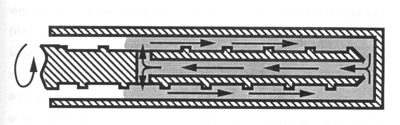

Recirculating Screw MixerThe recirculating screw mixer was designed as a laboratory intensive mixing machine with a well understood flow field for fundamental studies. It primarily consists of a small single screw extruder with a closed discharged and a hole bored down the center to allow for recirculation. The design goals for the recirculating screw mixer were:

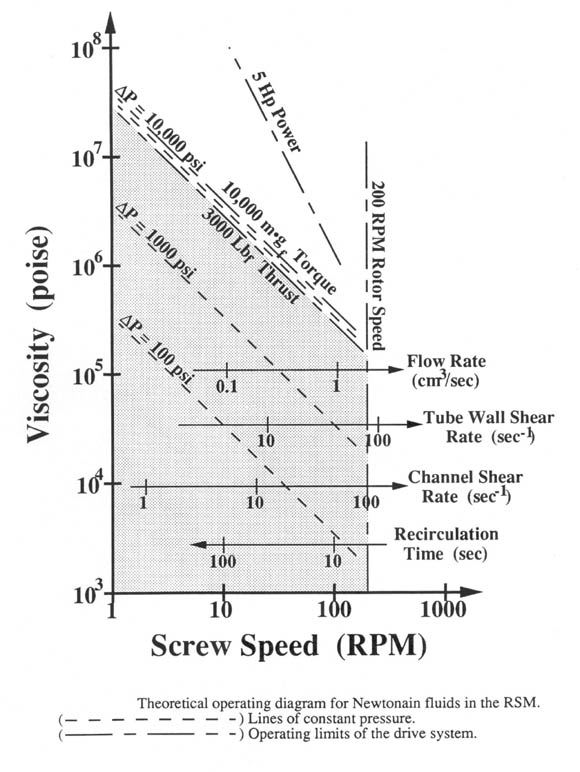

The first recirculating screw mixer made was designed to be used with a Haake torque rheometer and the Rheomix 600 base. With a 1.6 cm barrel, it has a free volume of 10.2 cm3. The complete mechanical drawings are available. In addition to the standard metal barrel, a poly(methyl methacrylate) barrel was provided to allow for flow visualization of the mixing process. The combination of well understood flow fields (channel flow in single screw extrusion and pressure driven flow through a tube) allows the recirculating screw mixer to be modeled in detail. Modeling< of the flow of Newtonian and power law fluids in the recirculating screw mixer provided the velocity field, operating diagrams, and methods for use of the mixer as a melt rheometer. The compounding capabilities of the recirculating screw mixer were tested with a polymer blend and a composite. Results were compared with a benchmark laboratory mixer and found to be similar. Details of this equipment and a few experiments which were conducted with it can be found in:

|

|

|

Copyright 2004-2008 Material Answers LLC |